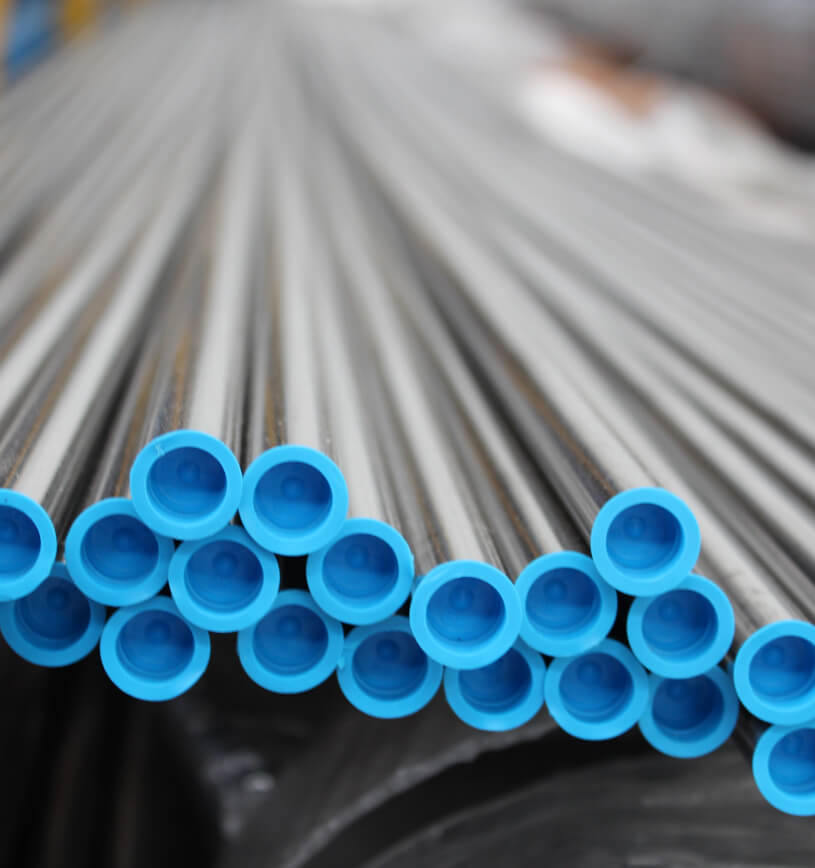

Manufactured in Germany from 1.4404 grade 316L stainless steel, Tubepress® is engineered to meet the high demands of modern industrial environments with unmatched durability, strength and reliability.

- Manufactured in Germany

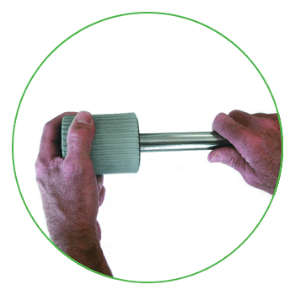

- 3-level press

- Cost saving installation

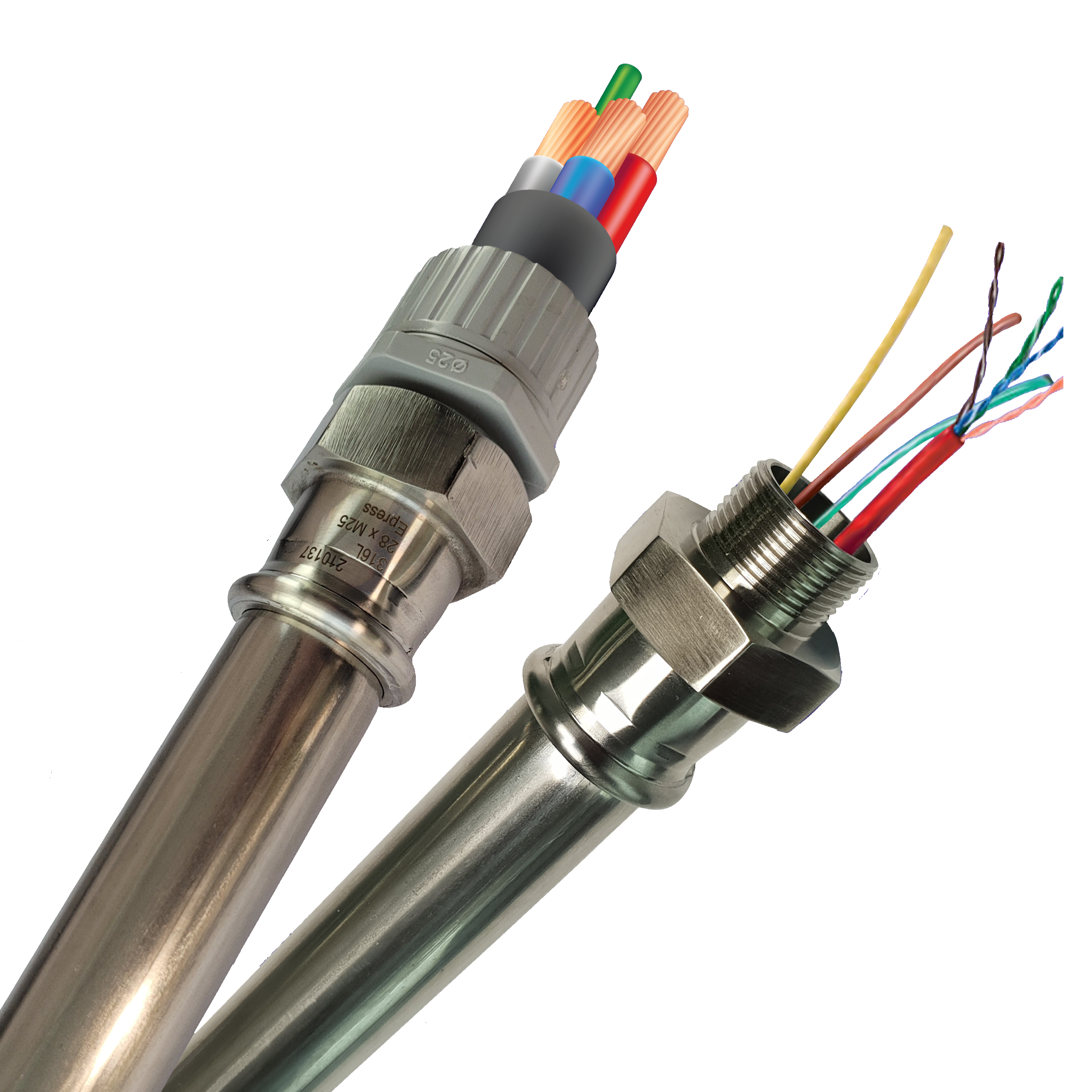

- The only press-fit system with a manufacturer-backed 40 bar fluid pressure rating

- 50 bar rating available upon approval

- All fittings have a 30-year press tightness guarantee

- Suitable for high-risk environments

- Watermark and Gas approved

- Environmentally friendly with no smoke, dangerous gases or toxic substances