Learning from history

In 2018, one of the largest meat processing facilities in South Australia broke out in flames, causing millions of dollars in damages. Investigations determined that a worker welding an offal bin had accidentally started the fire, which spread rapidly across the premise after it went into a highly combustible wall.

Had the workers not evacuated in the time that they did, the result may have been much more catastrophic. Although the devastating blaze broke out on a Wednesday, ripping its way through to Friday, this tragedy highlights only one of the dangers of welding.

Hazards at a glance

Although the pipe welding process may not be complex, the potential dangers are. Some of the risks to consider may include:

- Fire and explosions (as illustrated above)

- Airborne contaminants

- Radiation

- Electrical risks

- Burns and exposure to heat

- Eye damage

- Compressed and liquefied gases

- Noise

- Lead

- Confined spaces

- Ventilation.

Given the number of potential dangers in welding processes, several people are responsible for health and safety duties in relation to pipe welding. Those who have a role in managing the risks of pipe welding processes include:

- Persons conducting a business or undertaking (PCBUs)

- Manufacturers, designers, importers, suppliers and installers of plants, substances or structures, and

- Officers

Staff members and those at the workplace where pipe welding is to be performed also have duties under the Work Health and Safety Act, such as the duty to take reasonable care for their own health and safety at the workplace. As shown, there are many moving parts to a safe and efficient work environment for welding. But before we explore further, let’s discuss the basics of pipe welding.

Why weld pipe?

Staff members and those at the workplace where pipe welding is to be performed also have duties under the Work

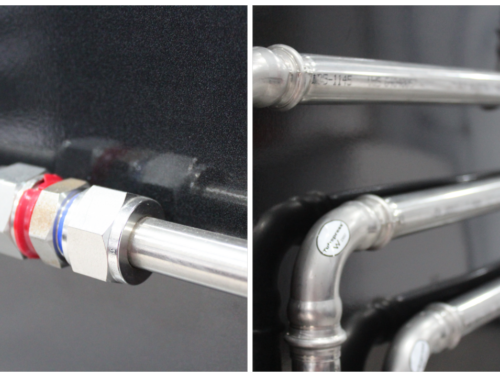

Pipelines are viewed as the veins of modern infrastructures and can be used in the transportation of oil, water, gas, and other important amenities. Therefore, pipe welding is sometimes necessary to perform repairs, construction, maintenance, and even replacements. However, it should only be conducted by certified personnel. The main aim of pipe welding is to ensure the entire system is secure and sealed. It is also important to note that varying grades of piping require varying welding processes.

The common types of pipe welding may include:

- Arc welding.

- Metal inert gas (MIG) welding.

- Tungsten inert gas (TIG) welding.

- Oxyacetylene welding and cutting

Arc welding

The welder must have an electrode and a welding gun in arc welding. A metal wire fed to the gun is heated until it melts. The molten metal applied to the pipe’s connection points creates the weld. Arc welding is suitable for heavy and thick metals such as cast iron.

Metal inert gas (MIG) welding

Metal inert gas welding is a form of arc welding most suitable for aluminium, mild steel, and stainless steel. The process entails the use of wire fed going through a wire electrode in a welding handgun. The process does not require any mixing of the gases, making it the quickest form of welding.

Tungsten inert gas (TIG) Welding

This form of arc welding requires an expert welder. Its application is similar to MIG welding, the only difference being the use of a tungsten electrode instead of a wire electrode to produce the arc. It has a clean finish making the welded pipe look attractive and professional. This type of welding is the most suitable for various metals and alloys such as magnesium, aluminium, and copper alloys. However, it is worth noting that different types of metals require different tungsten electrodes.

Oxyacetylene welding and cutting

This type of welding does not entail the creation of an electrical arc. It entirely involves the use of oxygen and acetylene to produce a super-hot flame. The flame can melt steel and create a strong weld. The filler rod is occasionally added to the welding area.

As opposed to other processes where welding machines are used, oxyacetylene welding involves the use of a torch attached to acetylene and oxygen bottles, a regulator, and gas hoses. It is suitable for soft metals such as bronze and copper.