There never seems to be enough time in the day, so anything we can do to save time is worth its weight in gold.

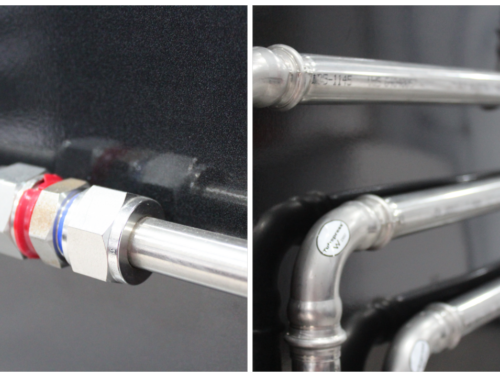

Press fit is a faster and easier solution to conventional pipe joining methods. This fitting type doesn’t require welding or soldering, so it can be installed much quicker than other methods.

So how much time can press fit actually save you?

There are lots of advantages associated with choosing press fit over other joining methods; one of the most important being its time saving benefits . The ‘fit and forget’ solution makes the pipeline fabrication efficient by more than 50 per cent in terms of the total time taken in project completion. It’s specifically designed to help installers work across their jobs more effectively. It also add versatility to popularly used pipeline systems, especially plumbing. Here’s how it ramps up the pace of installation:

1. Simple battery tools needed for installation

There is no need for welding equipment to install press fittings. The jointing of pipes can be completed in a matter of minutes using press fittings. Pipes of dimensions between 15 to 22 mm can be connected in less than a minute. This process used to take close to 15 minutes with welding. Such drastic reductions in installation turnaround times have revolutionised how pipeline fabricators and installers approach tube connections.

2. Easy assembly and checking before pressing

The need to alter pipelines due to installation errors, structural damage and maintenance are unavoidable. This is where the brilliant design of press fits shines through – the installer can assemble complex pipework arrangements and check for a perfect fit before pressing. For maintenance works, they can use slip couplings. This saves installers much time and effort compared to traditional pipework where rewelding is required, particularly where “hot work permits” are required. This can be a strategic advantage for you if you are a contractor working through tight schedules with your clients.

3. Ease of use in confined spaces

Press fittings are suitable for use in confined places and compact pipeline structures. When spaces are limited, there is always a risk of joints not being secure which would ultimately translate into damaged structures. Press fit offers the best jointing solution for jobs like this. The ease of use with which they integrate into pipelines saves installers’ time, besides the efforts that are otherwise required with brazing and welding.

4. Versatile applications in multiple industries

The press fit system is extensively used in various industries like petrochemical, pharmaceuticals, chemical plants and oil refineries. This is primarily because press fittings can be used with a wide range of materials like PVC, copper, stainless steel and carbon steel pipes. The popularity of press fit installations has grown in recent years as they are suited for both new constructions and retrofit projects.

5. Improvement in site safety

Fabricators and installers can work to complete their project undertakings in dramatically short turnaround times. Press fits are confidence-inducing, and this helps installers create an installation that improves the safety of the site where they are working.

6. Substitutes for compression fittings

Every installer is familiar with compression fittings needing room to rotate. This can be quite challenging, especially when pipes are buried underground. Compression fittinggs do not allow for this movement, and the joints become weak. Push fittings have built-in 0-ring seals, and they make great connections. This is an improvement over compression fits when it comes to saving installation time.

7. Material Handling

The ease of in-situ installation and the light weight of tube as opposed to pipe makes material handling a breeze. Tube is easier to carry and manipulate during installation, and the ability to install in-situ removes the need for pre-fabrication, saving both time and money as there is no need to freight bulky, awkward or heavy items to the site and no need for specialised lifting and shifting equipment.

Press fittings are built specifically to speed up the installation process using a minimalistic approach to jointing. It saves time and makes the entire installation process more secure and cost-effective. Combined with their corrosion-resistant and weatherproof nature, they benefit any project bound by time constraints.

Press fittings offer the convenience of use for installers without making any compromise on the quality of joints. The innovation has benefited customers worldwide with the remarkable turnaround time they can deliver.

If you’re looking for a way to save time on your next project, press fit is the way to go!