When it comes to industrial piping, it is important to consider the benefits and disadvantages and understand the key differences of available piping materials before deciding which material is best suited to your application.

While many different piping materials are used in industrial applications, the three most commonly used are stainless steel, steel and copper.

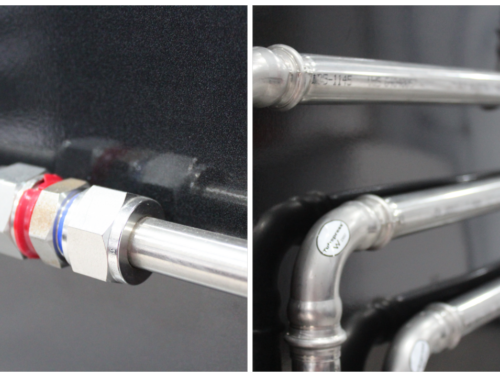

In this article, we will explore the differences between 316L stainless steel and Type B Copper so that you can make an informed decision on which one is best for your next project.

1. Corrosion Resistance

Corrosion resistance is the ability of a material to resist the corrosive effects of the fluids or gases flowing through them and any external corrosive factors. The corrosion can be general, localised or both.

One of the most important benefits of stainless steel is its corrosion resistance. This resistance is due to the passive chromium oxide layer that forms on the surfaces of stainless steel and renews itself quickly in the event of superficial damage, resulting in superior corrosion resistance in a vast range of applications.

When exposed to certain common environmental factors, copper can corrode, especially at elevated levels. These factors include gases such as carbon dioxide, sulphur dioxide, and hydrogen sulfide, ‘hard’ water with elevated levels of chlorine and/or chloride (also corrosive to stainless steel, but at higher concentrations) and a pH level over 6.5 – 7.0. Exposure to acidic environments can cause corrosion in the internal copper piping. In water pipes, this can cause water discolouration and copper poisoning.

While both stainless steel and copper will corrode given the right circumstances, stainless steel generally has greater corrosion resistance to a broader range of gases and fluids.

2. Strength and Durability

Stainless steel is, on average, 2.5 times stronger than copper and performs much better on the strain and stress tests. 316 Stainless steel tube has a tensile strength in the range of 570 – 620Mpa, approximately 3 times that of copper, and can withstand high pressures and temperatures without any issue.

Copper is a more malleable metal, making it easier to cut and bend, but it isn’t suitable for high-pressure or high-temperature applications.

3. Cost

The instability of copper pricing, rather than its cost, can cause major issues in a project. Stainless steel is a relatively stable commodity, and its pricing does not change as frequently as copper. This can help to keep a project on budget more effectively. It is increasingly common to find that stainless steel pricing is comparable, and in some cases cheaper, than copper.

4. Installation

Copper, as mentioned above, is a softer, more malleable metal. This means it can be bent easily, which may eliminate the need for some fittings in smaller sizes, but this entails additional skills and takes time. It also means that additional support may be required.

The strength and rigidity of stainless steel make it perfectly suited to long-run installations, often requiring less support than copper. Stainless steel may also be lighter than a copper tube, as the wall thickness can be less while achieving the same pressure rating, making installation easier.

5. Environmental Impact

Stainless steel is a sustainable material that can be reused and recycled. It also has a low carbon footprint thanks to its ability to be produced without the use of harmful chemicals.

Copper is also a sustainable material with a low carbon footprint. However, it can cause environmental pollution if not properly disposed of.

6. Applications copper cannot be used in

Copper cannot be used in the below applications:

- Diesel fuel pipework. Copper pipework can cause fuel to polymerise (thicken)

- High-pressure systems (limited to the pressure rating of the copper tube, which drops dramatically as size increases)

- High-velocity systems, due to the rate of corrosion increasing significantly as flow increases. A copper tube with a flow rate of 2 m/s will corrode 3 times faster than stainless steel and 20 times faster than stainless steel when the flow rate is 6 m/s.

Both stainless steel and copper have their advantages and disadvantages. Besides, from a very small number of applications, stainless steel can be used in every application in which copper is used and in many applications where copper cannot be used. Stainless steel will provide a long-lasting, high-quality solution with better corrosion resistance, strength and ease of installation.

To speak to one of our experts about using stainless steel in your project.