In the fast-moving world of construction and industrial sectors, efficiency is more than just a luxury—it’s a must.

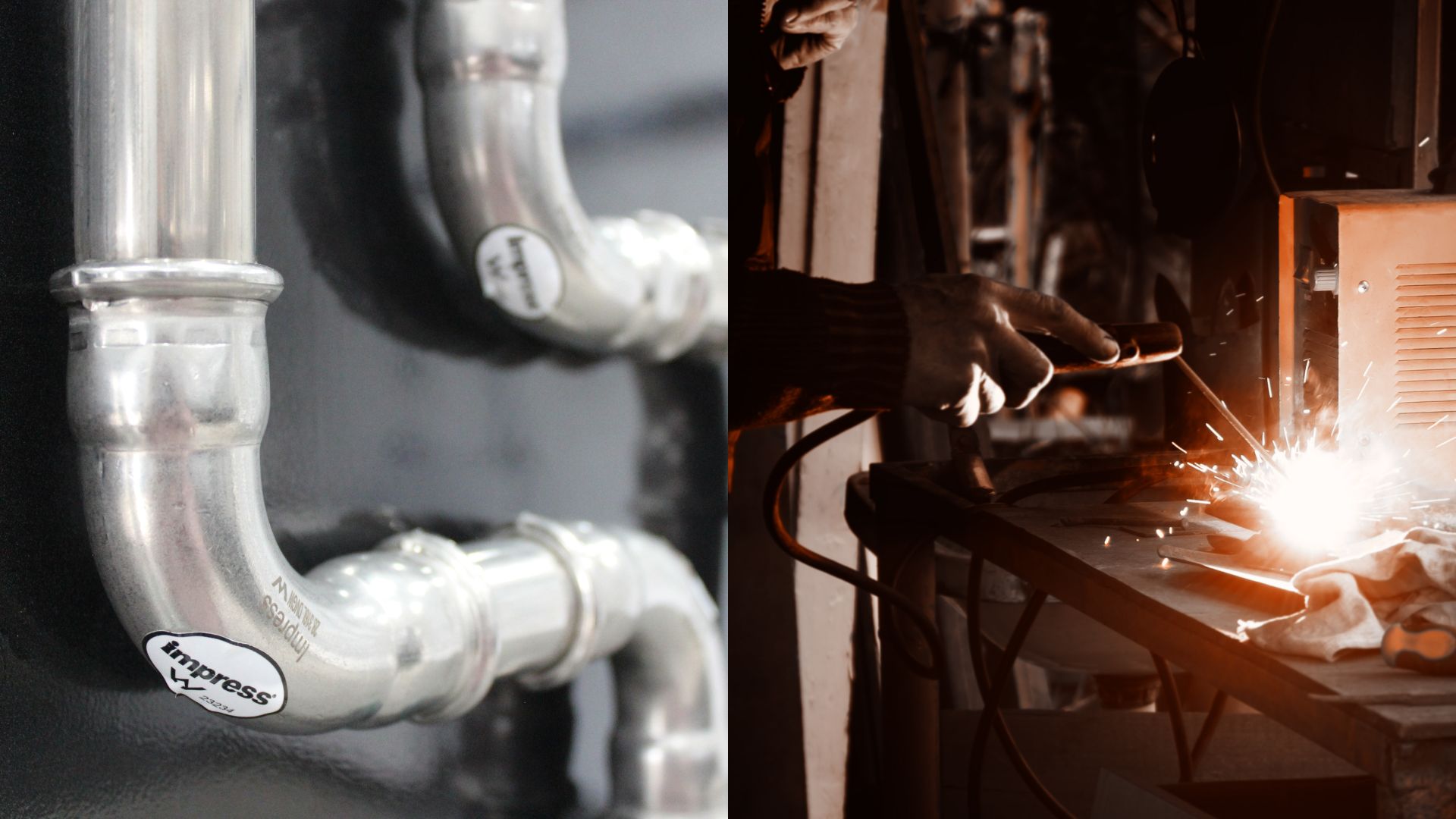

When it comes to joining pipes and tubing, press fittings are quickly becoming the method of choice, challenging long-standing techniques like welding (for steel & stainless steel) and silver soldering (for copper). Choosing the right one for your stainless steel pipes requires a solid understanding of both methods and how they align with the specific needs of your project.

In this article, we’ll explore the benefits and drawbacks of each method, so you can make an informed decision about which solution will work best for your needs.

What are press fittings?

Press fittings are a quick and reliable way to join pipes without the need for welding or soldering. It works by inserting a pipe into a specially designed fitting and then using a pressing tool to crimp the connection. This process creates a strong, leak-proof seal in just a matter of seconds.

Because it doesn’t require heat or open flames, press fit is a much safer option. This makes it an ideal replacement for traditional piping and for environments where traditional methods might be impractical, such as confined spaces or occupied buildings.

Press fittings are a popular choice in plumbing, HVAC, and industrial settings because it’s durable, easy to install, and built to last.

How it Works

Instead of heat, our Press Fit technology uses press tools to securely connect pipes or tubing in just five simple steps. This means faster installations, reduced labour costs, and a safer work environment.

Advantages of press fit

- Faster installation saving time & money: Press fit cuts installation time dramatically compared to soldering or welding. Joints are completed in seconds, making it perfect for large-scale projects or tight deadlines.

- No permits, no delays: Since press fit doesn’t require heat or flames, there’s no need for hot work permits or extra safety measures. This means fewer delays, less paperwork, and a smoother installation process—especially in places where traditional methods would require shutdowns or special precautions.

- Leak-proof and reliable: A properly pressed connection creates a strong, secure seal that resists leaks and maintains system integrity for years, reducing the risk of costly repairs.

- Works with multiple materials: Press fit isn’t limited to just one type of pipe. It’s compatible with stainless steel, copper pipes, and PEX, making it a versatile solution for a wide range of plumbing and industrial applications.

Disadvantages of press fitting

- Specialised tools: Press fit requires specific tools which may not always be readily available in remote areas or for urgent repairs. But with the right equipment on hand, the process is significantly faster, more reliable, and reduces labor costs compared to traditional methods.The time saved on faster, safer installations makes press fit the most cost-effective solution. Many suppliers offer hiring of press tools.

What is soldering?

Soldering, also called sweating, is a traditional way of joining pipes that has been around for a long time. It involves heating both the pipe and the fitting until they’re hot enough to melt the solder, which is then applied to seal the joint.

Once the solder cools, it hardens and creates a strong bond between the two pieces. Even though this method has been used for decades, it’s still widely used in plumbing today, especially for smaller-scale projects and repairs.

Advantages of soldering

- Reliable joints: When performed correctly, soldered joints can be as strong as the pipes themselves, ensuring a durable connection.

- Material compatibility: Soldering is suitable for various metals, allowing for flexibility in different piping systems.

Disadvantages of soldering

- Time-consuming: Soldering is a more time-consuming process, especially on larger projects, because it involves heating the pipes to high temperatures before soldering can commence.

- Requires skill & specialised equipment: Getting a strong, reliable soldered joint takes specialised equipment, skill and experience. Without that, there’s a higher chance of mistakes, which can lead to leaks or failures down the line.

- Fire hazards: Since soldering uses open flames, it comes with fire risks and may require extra precautions like hot work permits to keep things safe.

- Challenging surface preparation: For soldering to work, the pipes need to be clean and dry. This can be tricky in environments where the pipes are wet or damp, adding extra steps to the process.

- Ongoing consumables cost: Soldering (and welding) both require consumables like flux, silver solder, solder wire, or filler rods. Over time, the need to replenish these materials can drive up operational costs, especially for large-scale or repeated installations.

- Exposure to hazardous fumes: The soldering (and welding) process can release harmful gases and fumes, including lead fumes (in lead-based solder), rosin flux smoke, and metal oxide particles. These pose health risks if proper ventilation and personal protective equipment (PPE) aren’t in place. This adds not only complexity but also a duty of care to ensure safe working conditions.

What is welding?

Welding is a long-established method of joining metal components by using high heat to melt the edges of pipes or fittings and fuse them together. Once cooled, the joint forms a solid, continuous piece of metal. It’s a go-to solution for stainless steel systems, especially in industrial and infrastructure projects where strength and durability are non-negotiable.

Advantages of welding

- Strong, permanent joints: Welding creates a fully fused connection between two metal surfaces, making it durable when done correctly. In high-pressure, high-temperature environments, a properly executed weld can hold up for decades without failure.

- Handles high heat and pressure: Welded joints are commonly used in environments that experience extreme stress, such as chemical plants, water treatment facilities, and heavy industrial systems.

- Widely understood: Welding is a well-established trade across the construction and industrial sectors. Many technicians and fabricators are trained in welding techniques, making it a familiar process on job sites.

Disadvantages of welding

- Labour intensive: Welding takes time, not just to perform the welds, but also to prepare the pipe surfaces, line everything up precisely, and ensure safe conditions. This can slow down project timelines, especially when many joints are involved.

- Requires skilled trades: A quality weld depends heavily on the skill of the welder. Mistakes like cold joints, incomplete penetration, or inconsistent welds can lead to weak points, corrosion etc and increase the risk of leaks or failures later on. Often welded systems are x-rayed after installation to check the integrity of welding, a very costly exercise!

- Hot work risk: Because welding involves open flames or high heat, it introduces fire hazards—especially in environments with flammable materials or restricted ventilation. Hot work permits are required, along with fire watches and added safety procedures, which can delay work.

- Not ideal for live environments: Welding usually requires system shutdowns, isolation of work areas, and sometimes full evacuations of buildings or plant rooms.

- Expensive tools & equipment: Welding requires specialized welding machines and equipment including weld screens and other specialised protective safety items. Welding PPE for personnel is extensive and can include fume extraction systems. Substantial electrical power supply is required too, all adding to the costs.

- Rework & repairs: Very difficult and expensive.

Key differences: Press fit vs soldering and welding

| Factor | Press Fit | Welding | Soldering |

| Speed | Very fast | Slow | Moderate |

| Skill required | Low | High | Moderate |

| Safety | No flame, safer | Fire risk | Fire risk |

| Installation cost | Lower labour | High labour | Moderate labour |

| Maintenance | Easy to repair or adjust | Complex repairs/rework | Rework needed for leaks |

| Material | Stainless, copper, PEX | Stainless steel, steel | Copper, brass |

| Best for | Commercial, industrial, residential, retrofits | High-pressure steel systems | Residential copper piping |

Best use cases for each method

Choosing the right method for joining pipes depends on the specific needs of your project, such as its scale, environment, and safety requirements. Each method has its own unique advantages depending on the situation.

Press Fit

- Commercial, industrial & residential builds: Speed, safety, and long-term performance make it ideal for large-scale stainless or copper systems.

- Retrofits and repairs: Quick fixes with minimal disruption.

- High-pressure, high-heat systems: Engineered for durability and reliability.

Soldering

- Residential or small commercial plumbing: Lower pressure and smaller pipe sizes suit soldering well.

- Custom or detailed copper work: Great for tailored plumbing solutions where time isn’t a major constraint.

Welding

- Heavy-duty steel systems: When pipe specs require full fusion or extreme temperatures.

- Offsite fabrication: Controlled environments reduce the safety concerns of onsite welding.

- Projects with skilled welders on hand: Labour availability can be a key factor.

Experience the best in press fittings with Ibex Australia

At IBEX Australia, we’re not just another supplier, we’re the team behind safer, stronger, and more efficient piping systems. With over 30 years of industry expertise, we know that reliability isn’t just a feature, it’s a necessity. That’s why we provide premium stainless steel press fittings that make installations faster, safer, and hassle-free—no welding required.

We don’t just hand over products; we work alongside you, offering expert advice and tailored solutions to ensure your system is built to last. Whether it’s a large-scale installation or a complex upgrade, we’re here to help you navigate the challenges and get the job done right the first time.Let’s make your next installation seamless. Explore our range of press fittings today and get in touch with our expert team about the right press fittings for you.