Fire is one of the most devastating hazards in the world. A small spark could erupt into a larger fire or even an explosion, destroying property and endangering human lives. Our article Potential Dangers of Pipe Welding has been illustrated in detail.

As developers are at the drafting stage of a structure, engineers and architects must pay close attention and consider building material options that can prevent, contain and even deter a fire.

There has been an ongoing discussion about the fire resistance of stainless steel. This is a common enquiry from industry-related members, especially those in construction. Although there is no official “fire rating” for stainless steel, many fire tests have been done by the Nickel Institute and others to compare how different metals perform.

According to the Australian Stainless-Steel Development Association (ASSDA), the question “What is the fire rating of Stainless Steel?” can be answered in the following three parts.

1. Will stainless steel burn, and if it does, will it emit fumes or facilitate the spread of fire?

The fact that the material is steel already presents a self-answered question. It is recognised that steels do not burn and only starts to melt at about 1400 degrees Celsius. This means that stainless steel does not have a “fire rating” as such, so the AS/NZS 1530.3 tests (Methods for Fire Tests on Building Materials, Components and Structures) are not required.

2. Will stainless steel provide a barrier to flames, and if it does, how rapidly will the heat penetrate the barrier to cause damage on the far side?

A satisfactory demonstration had been previously carried out by a British Stainless Steel Association (BSSA) member, Stewart Fraser Ltd. Fraser, had testing done on 316 type doors and frames to test their fire resistance. This test lasted two hours and ten minutes.

In the end, it showed a temperature of only 98 degrees Celsius on the ‘safe’ side of the door. The doors and frames suffered minor discolouration and thermal distortion of the steel. However, the doors maintained their absolute structural integrity throughout the test. This test proved that 316 stainless is a great choice for fire resistance and prevention.

3. What effects (both during and after an event) on the mechanical properties of stainless steel? How do these compare with structural carbon steels?

Some reliable tests and demonstrations prove that austenitic and duplex stainless steels have superior high-temperature properties compared to carbon steel. The table below shows the deflection and failure modes of three-metre-long commercial electrical cable trays loaded to simulate actual loadings. They were heated with 18 LPG burners to obtain an average temperature of 1000 degrees Celsius to 1050 degrees Celsius from five minutes to more than 45 minutes.

| Material | Result | Comment |

| 316L Stainless Steel | Maintained integrity for five minutes. Burners continued until gas exhausted after 45 minutes. Centre sag 80.5mm – see picture below. | Maximum average ladder temperature 707°C with max. Individual 757°C. |

| Galvanised Carbon Steel | Maintained integrity for five minutes. Centre sag 166.5mm. | Molten zinc dripped. The maximum average ladder temperature is 642°C. |

| Aluminium | Collapsed after 26 seconds. | Fell outside the monitoring zone, so no temperatures were measured. |

| Fibre Glass | Collapsed after all burners ignited. | Subsequently ignited with fume emission. |

As stainless steel cannot burn, it would not aggravate spreading flames in the case of a standard structural fire. Stainless steels are also selected for their oxidation resistance and strength at high temperatures. This resistance depends mainly on the amount of chromium in the steel. (Read more about the makeup of 316L stainless steel here ). Thus, stainless steel is the best choice for fire safety and prevention regarding construction materials and life-cycle costs.

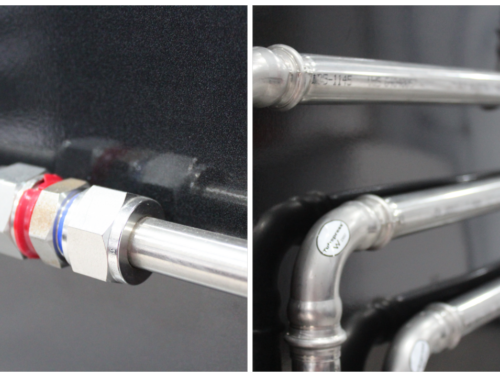

316L stainless steel is best suited for the manufacturing of medical, marine and food applications. It has better non-magnetic properties than other stainless ones. Due to that, it is popular in wire cloth, springs and hose braiding. You can also see stainless steel in coastal architectural panelling, chemical and petrochemical equipment, and engineered components.

The Safest Choice

There is a lot of research comparing carbon steel, aluminium and galvanised steel to stainless steel. The overwhelming conclusion is that stainless steel outweighs these other metals in corrosion resistance, durability, life-cycle cost savings, and fire prevention. The economic benefits and fire safety aspects are unmatched.